The Conformité Européene (CE) certifications are standards approved by the European Union to indicate a product meets EU safety, health, and environmental protection requirements. They are only enforced in the EU, but as many larger manufacturers sell into the EU they are default international standards for many products.

EN 17092 Standard

EN 17092:2020 is the CE standard for motorcycle protective clothing, replacing the older EN 13595 professional riders standard (which was in some aspects more stringent but often ignored). It aims to give leisure riders some assurances about minimum protection provided by a garment rather than having to trust manufacturer claims.

Many garments being sold as motorcycle gear for motorcycle riders might look strong but fail to provide adequate protection at riding speeds. We notice this a lot in New Zealand, many riders are dressed like RoboCop but in gear that has never been tested for crash impacts, potentially might tear or move to expose the body in a fall, or which are misleading in their claims to meet standards.

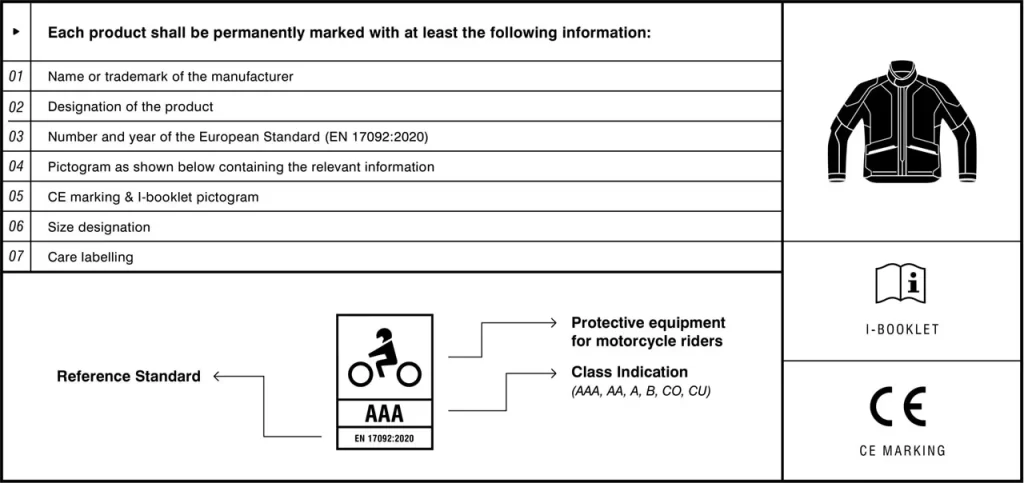

A “CE Approved” garment has had several parts of a garment tested to surpass the minimum requirements in a certified testing facility. A garment sold in the EU claiming to be protective motorcycle apparel must be CE Approved. Many other countries don’t enforce any requirements on protective gear but manufacturers might get some tests done anyway to backup their protective claims. A “CE Certified” garment indicates only that some garment samples were tested, but not necessarily all critical parts, and a “CE Tested” garment indicates the garment or some piece was tested in the manufacturer’s own facility.

A garment lacking a CE Approved label with supporting documentation does not necessarily mean that it is unsafe to wear, but the larger reputable manufacturers do invest the expense of certification and include CE Approval if their garments pass. In Australia MotoCap (https://www.motocap.com.au/) also performs highly-respected and independent EN 13595 tests on motorcycle gear and aims to cover about 25% of gear sold there.

The EN 17092 tests check for abrasion resistance while sliding along a road surface (simulating an asphalt road), tear strength to ensure the garment won’t rip apart during an accident, seam strength, dimensional stability when washing, and that it only contains innocuous chemicals that are not irritant to the skin nor environmentally harmful.

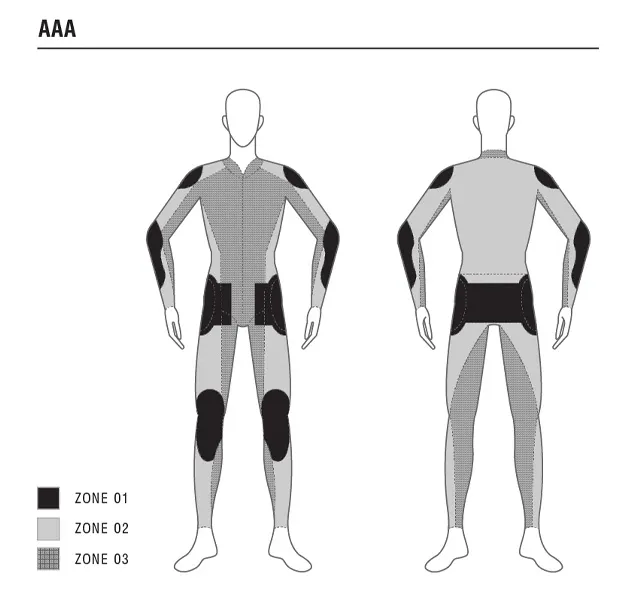

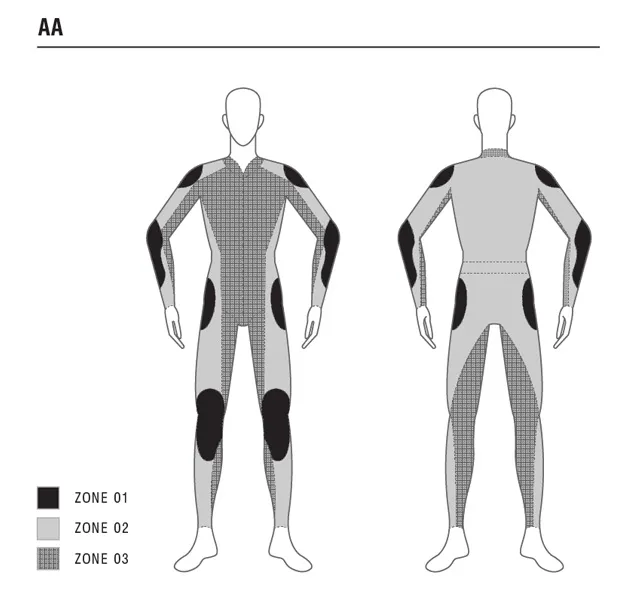

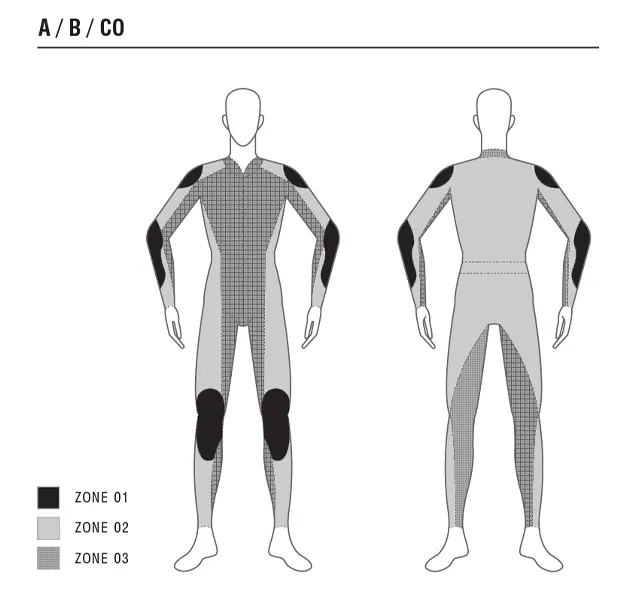

EN 17092 has five levels of protection where the severity of testing depends on three designated zones:

- Class AAA which is the highest level of protection offered under the standard, so worn in situations with the highest risk, and which must include elbow, hip, knee, and shoulder impact protection.

- Class AA which is the second highest level of protection under the standard, suitable for a wide range of risks that riding presents, and also must include elbow, hip, knee, and shoulder impact protection.

- Class A which is the third highest level of protection, also with elbow, knee and shoulder protection, optionally also including hip protection.

- Class B have passed the same level of abrasion resistance as Class A garments but which are not tested with or do not have impact protectors in place.

- Class C garments which hold at least one impact protector but do not themselves offer abrasion resistance, so should be worn combined with an AAA, AA or B garment.

AAA garments offer the highest level of protection in the standard but are typically heavier, more expensive, hotter and less comfortable. It does not imply that the garment is sufficient on its own for high speed track racing, although tracks might mandate such gear. Class AA is generally suitable for most touring and long-distance motorcycle riding. Class A garments are lighters and more comfortable, generally suitable for urban riding, commuting, off-road enduro, cruising, and warmer environments.

Although two garments might both pass as class AAA, it does not mean that they provide equal protection. Custom leather racing suits far exceed the AAA abrasion requirements, some aramid denim (such as kevlar) jeans manage to satisfy AAA but so do spectra jeans which are 40% more abrasion resistant. It should be remembered that the standard is designed for minimum requirements and intended for leisure activity, not professional riders.

EN 1621 Standards

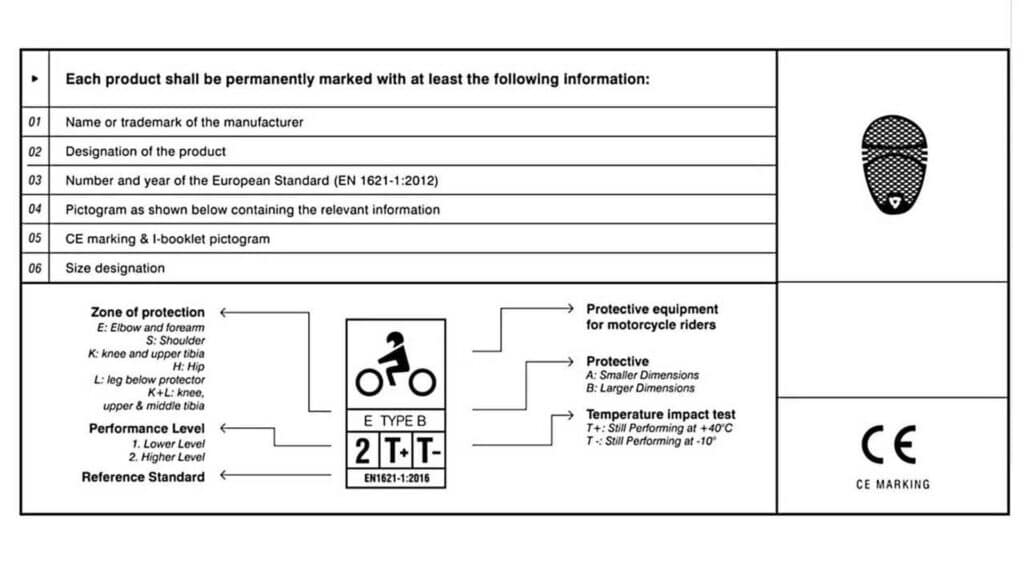

Impact absorption have separate tests depending on the body armour:

- EN 1621-1:2012 for elbow, hip, knee, shoulder protectors,

- EN 1621-2:2014 for back/spine protectors,

- EN 1621-3:2019 for chest protectors.

The body armour that passes the tests are either rated as level 1 or level 2, depending on how much an impact force is transmitted through to the body, with level 2 giving superior impact protection (level 2 allows under roughly half the amount of force to be transmitted versus level 1).

Body armour is also designated as Type A for protectors that cover a smaller area or Type B for larger area. It is important that an impact protector cover sufficient area of a zone and remain in place for it to be effective, but that may depend on the garment sizes. Optional T+ and T- designations are included if the armour was also tested at higher temperature (40 degrees Celsius) and/or lower temperature (-10 degrees Celsius).

It is important to realise body armour might not prevent a fracture at high speed or with compounding factors, but evidence points to it reducing the risk and severity of fractures, particularly for boots with ankle fractures (and always helmets). Evidence for back protectors reducing spinal injuries is less conclusive.

Protective Gear for PEV Riders

EN 17092 and the EN 1621 are EU standards. Unlike with bicycle helmets New Zealand lacks its own standards for garments that claim to be protective. However, the EU standards are by far the most widely recognised standards for motorcycle gear around the world, and motorcycle gear is often chosen by PEV users as being suitable for their riding.

The EN 1621 standards have been widely adopted by reputable body armour manufacturers, such as Leatt and Knox, for certifying impact protection. However, most buyers are unaware whether their armour meets the lower level 1 or higher level 2 standard, or even that there are different levels.

Most protective garments that are currently worn by PEV riders have no certification against abrasion. Even Leatt, which is a highly respected moto and mountain bike brand, has only a few garments that are certified against abrasion, likely as their target market are mostly off-road riders. That’s why at Atomic EV we also provide Knox motorcycle gear, expanding our range from the class A Action Pro, to include class AA and AAA garments, with level 2 body armour, and including both men’s and women’s selections.

Garments that are not designed for road riding might tear, wear through or break apart at a seam during a road accident. Many people forget that the majority of significant road injuries are due to abrasion rather than fractures. This is especially important in New Zealand due to the prevalence of chip seal on our roads, which is about 4.5 times more abrasive than the asphalt more common in the EU.

That doesn’t mean all PEV riders need to invest in class AAA gear or wear expensive and hot leather outfits, but more awareness is required in the community about adopting abrasion standards, particularly when riding on our roads. Depending on riding needs, the best choice will be a balance between protection, cost and comfort.