Lithium-ion batteries are very widely used in many consumer electronics. Compared to most other rechargeable battery technologies, lithium-ion batteries have high energy densities, low self-discharge, and allow recharging between 300-15000 full cycles. This makes them particularly suited for powering personal electric vehicles.

However, they do reduce their capacity and/or increase their resistance through repeated usage, so its good to understand how to care for the battery in your PEV to maximise its lifetime. They can also be a significant fire hazard if handled inappropriately, so all consumers should have a basic understanding of battery safety.

How lithium-ion batteries work

Lithium-ion batteries rely on chemical reactions which release and absorb electrons.

At the anode (negative terminal) a chemical half-reaction releases a lithium ion and frees an electron. The electron can flow outside the battery via the anode through an electric circuit (providing it power) to the cathode (positive terminal) of the battery. The lithium ion migrates through the electrolyte within the battery. At the cathode the electron combines with a lithium ion in another chemical half-reaction.

The anode is typically made from carbon (graphite), the electrolyte from either a liquid lithium salt or a solid lithium metal oxide, and the cathode from various lithium composites with other metals (such as iron, manganese, or cobalt).

The composition of the cathode affects the voltage between the anode and cathode, but typically is is around 3.6 Volt on a fully charged battery.

Overdischarging the battery results in a different chemical reaction which is irreversible (damaging to the battery) and buildup of (potentially hazardous) lithium dendrites on the anode, but otherwise the two half reactions can be reversed by applying an voltage via an external power supply. Similarly, overcharging the battery to 5.2 Volt likewise results in another (potentially hazardous) chemical reaction.

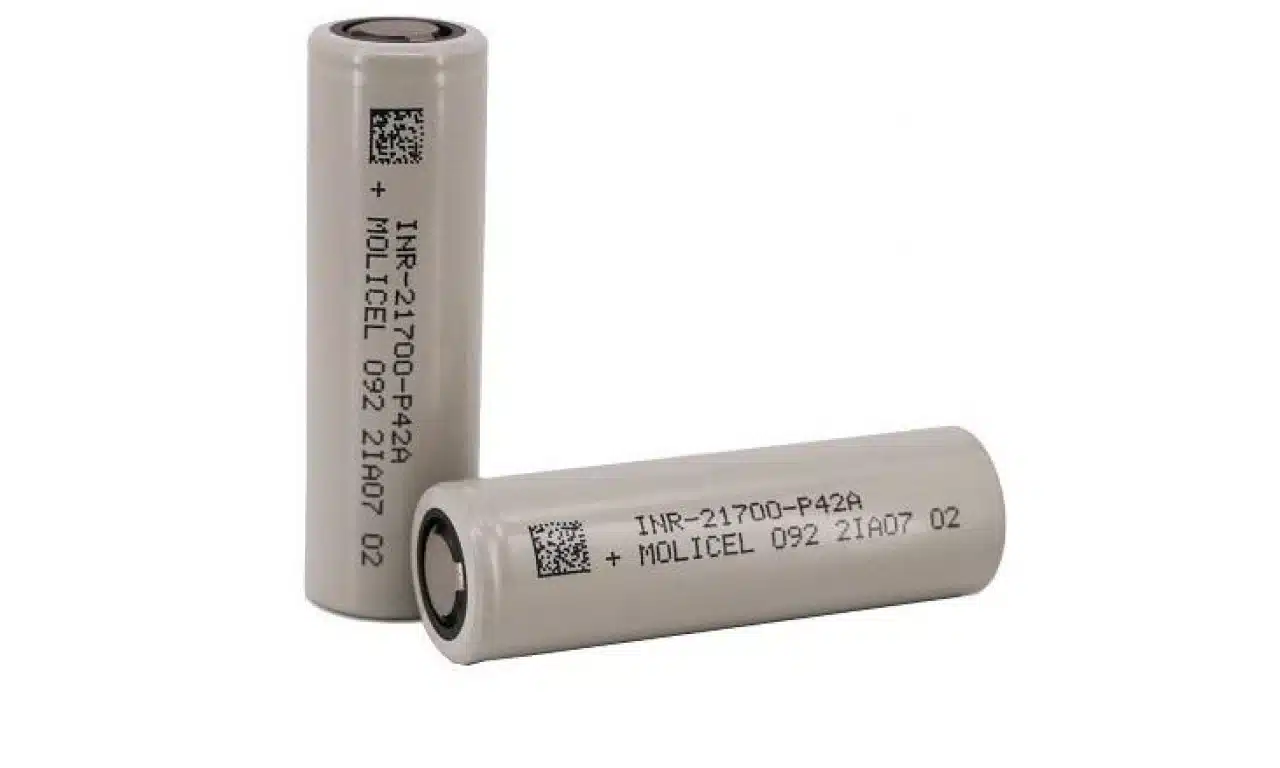

Lithium-ion batteries come in various sizes and shapes but the most common are the 18650 and 21700 battery standards. The 18650 (or 1865) has an 18 mm diameter cylinder that is 65 mm long, whereas the 21700 (or 2170) has a 21 mm diameter cylinder that is 70 mm long, giving it 47% more volume and so greater energy capacity.

As a single lithium-ion battery only provides around 3.6-3.7 Volt, multiple batteries are connected together in series (daisy chain) to increase the total voltage. To give greater energy capacity larger battery packs also combine batteries in parallel to provide greater current or energy capacity.

Battery packs denote this by an mSnP nomenclature, where a total of mn batteries are arranged as m in series (to give m x 3.6 total volts) grouped as n in parallel.

For example, the Meepo Hurricane uses a 12S4P 21700 Molicel P42A battery pack, so has 48 battery cells arranged with 12 series of 4 parallel batteries to give total 43.2 Volt (peak 50.4 Volt). Each P42A battery has 4.2 Amp-hour capacity, or 4.2×3.6=15.2 Watt-hour capacity, so the battery pack has 726 Wh capacity. The KingSong F22 Pro instead uses a 42S4P 21700 Samsung 50S battery pack, with each cell having 18.5 Watt-hour capacity, so the battery pack has total 155.4 Volt (using 3.7 Volt/cell) with maximum potential 176.4 Volt (using 4.2 Volt/cell) and 3108 Watt-hour capacity. Other high-end EUCs often use a 36S4P configuration of 50S cells and state 151.2 Volt (their maximum voltage), whereas their nominal voltage is actually 133.2 Volt and have 2664 Watt-hour capacity.

One advantage of having higher voltage battery packs is that higher voltage motors generally have higher power output and are more energy efficient than low voltage motors.

All but the cheapest battery packs have a battery management system built into the battery pack or even on individual battery cells. It is responsible for ensuring no battery cell drops under the minimum voltage during use nor going above voltage during charging. A battery management system can also rebalance the battery cells, detecting when some cells differ in voltage from each other and either actively shifting capacity between cells or selectively rebalancing during the next charge.

Charging guidelines

Regardless what is explained here it is important to always follow the manufacturer recommendations for their batteries, and their instructions override any conflicting suggestions.

First, and most importantly is to always use a manufacturer-approved charger (or at least a certified charger with identical characteristics). Overcharging using an incorrect charger can damage the battery and might be extremely dangerous.

Never full discharge a battery. Most batteries include a battery management system that switches off the battery when it gets close to full discharge to avoid the risk of overdischarging and excessive dendrite buildup. However, lithium-ion batteries do have a small self-discharge rate (around 1.5-2% per month), so should not be left at very low charge for extended periods (such as over the winter months). Most manufacturers recommend storing batteries longer term at between 30-50% of their capacity, and periodically giving the battery a small partial recharge to keep it within that range. It is best to recharge the battery periodically rather than waiting for the battery to be near depleted, so more frequent charging of the battery rather than letting it run all the way down.

Unlike lead acid batteries, lithium-ion batteries are best not stored at full or high charge, as it gradually reduces the amount of available lithium ions and can increase battery resistance. So if a vehicle is not going to be used for a few days it is preferable to only charge to 80% after a ride. More partial recharge cycles rather than fewer full recharge cycles can result in a longer lifetime for the battery. However, some manufacturers do recommend occasionally performing a larger (but not full) discharge.

If a battery is fully charged then it won’t be able to be charged further with regenerative breaking (ie no brakes) until it has discharged slightly, as the battery management system must ensure the battery is not overcharged. Remember this whenever charging a PEV such as an EUC or electric skateboard at the top of a hill.

Although high-current fast chargers are made available by some manufacturers for certain batteries it is generally acknowledged that recharging at a slower rate is better for battery health.

For some but not all manufacturers, it is recommended to wait for a battery and vehicle to cool 30 minutes after extensive use before connecting a charger. Cold batteries are less efficient and very hot batteries can be dangerous, so batteries should only be stored and used in environments between 0 and 40 degrees Celsius, and ideally between 10 and 25 degrees. Likewise, it is good practice to let a wet vehicle drip dry before charging in case the charging terminals or exposed connectors are wet.

Some manufacturers recommend leaving their charger plugged into the battery when not in use, as their battery management system just trickle charges and rebalances the battery and the charger connectors help keep the battery terminals covered and free from dirt and moisture.

Safety considerations

Lithium-ion batteries are used daily in many millions of devices around the world, and incidents are extremely rare, particularly with the premium batteries and smart battery management systems used in most PEVs. However, it is worthwhile to be aware of relevant safety considerations.

Batteries are more at risk after a heavy impact or puncture, when exposed to water, when left for extended periods at very low charge, or when recharging. Particularly during these times the battery should be kept away from any flammable items and must not be left near an emergency exit (so not left to charge near the only entrance to an apartment or office in a high-rise building).

If a battery is suspected to have been damaged in an accident, and especially if it swells, smells, releases smoke, or makes any hissing or clicking noise it is imperative to urgently evacuate the area and call emergency services. Only if there is no risk to individuals the battery might be moved away from any flammable items, ideally outdoors to reduce the potential of smoke damage, and left to cool, potentially covered with a fire blanket or inside a fire-resistant case. Do not later attempt to use the battery, nor put it in a car or bring it in to show us, instead you can take photos from a safe distance and contact us.

Do not short circuit the connectors and never open a battery pack nor modify the battery. It is easy to accidentally short the internal wiring or introduce a conductive contaminant into the battery enclosure. Any evidence of moisture ingress into a battery pack is dangerous and usually requires discarding the entire battery pack.

Bypassing the operation of the battery management system can be dangerous, as if any battery cells are significantly imbalanced from others then low voltage cells might fully discharge during use even if the other cells still have charge. Likewise a high voltage cell might overcharge during recharging while other cells still need to finish recharging.

Although commonly ignored it is best to never leave a charging battery unattended, and never leave in a hot location such as in car on a sunny day. It should be stored and charged away from flammable materials, and avoid charging when the vehicle is wet. Do not block or cover the battery or charger when charging as some heat is normally generated during charging.

If a battery pack has leaking fluids, do not touch any fluids. Dispose of a leaking battery pack. In case of eye contact with fluid, do not rub eyes. Immediately flush eyes thoroughly with water for at least 15 minutes, lifting upper and lower lids, until no evidence of the fluid remains. Seek medical attention.

Keep the battery away from children.

Never discard lithium-ion batteries in general waste, they must be recycled, as they can ignite when crushed in waste collection trucks and eventually leach toxic compounds in landfills. Consumer NZ has an article on battery recycling (https://www.consumer.org.nz/articles/how-to-recycle-used-batteries) and wasteMINZ a map (https://www.wasteminz.org.nz/nz-facilities-that-collect-batteries) of where they can be dropped off for recycling in each New Zealand region.

If any battery cell within a pack is overheated or overcharged, thermal runaway can occur where an overheating battery ignites neighbouring batteries in a pack. This can result in a fire that burns at over 500 degrees Celsius, challenging to extinguish even for professional firefighters, and releases a mixture of toxic smoke. The fire can unpredictably restart and grow as more cells progressively catch alight.

A small lithium-ion fire can be handled like other combustible fires, with a foam extinguisher, CO2, ABC dry chemical extinguisher, powdered graphite, copper powder, soda (sodium carbonate), or halon. Class D fire extinguishers are not used on lithium-ion fires, but instead on lithium-metal fires.

Water-based products can be used to cool a lithium-ion battery since they contain very little lithium metal (which would react strongly with water). Water also cools the adjacent area and prevents the fire from spreading. Sand is another option.

A large lithium-ion fire is often carefully left to burn out by itself as water is ineffective. Allow plenty of air ventilation to reduce smoke damage and avoid the toxic fumes. Lithium-ion fires do not need oxygen to burn, so smothering with a fire blanket or sand is only really effective at preventing the fire spreading further and to extinguish other battery components that are burning. The burning battery can be cooled to reduce the risk of further battery cells catching alight by dosing with large quantities of water.